Use a tool to make a tool

I find project development enjoyable right up until the point of having to connect things to a PCB. Wiring connections is a tedious chore. It's all easy when using a breadboard and cheap 20cm dupont ribbon cable jumpers. Unfortunately I've been burnt many times using those same jumper wires on "production" systems - the connectors quickly become loose and the wires themselves have lousy inflexible plastic coating what must be the finest of copper threads. Just downright terrible reliability.

The solution is to build custom cables with decent connectors and wires. It's a lot of effort though. It's even more difficult when the connectors are getting smaller, the eyesight is getting less acute and the fingers loosing their dexterity. Even with a high quality Japanese crimping tool, every connector is a struggle.

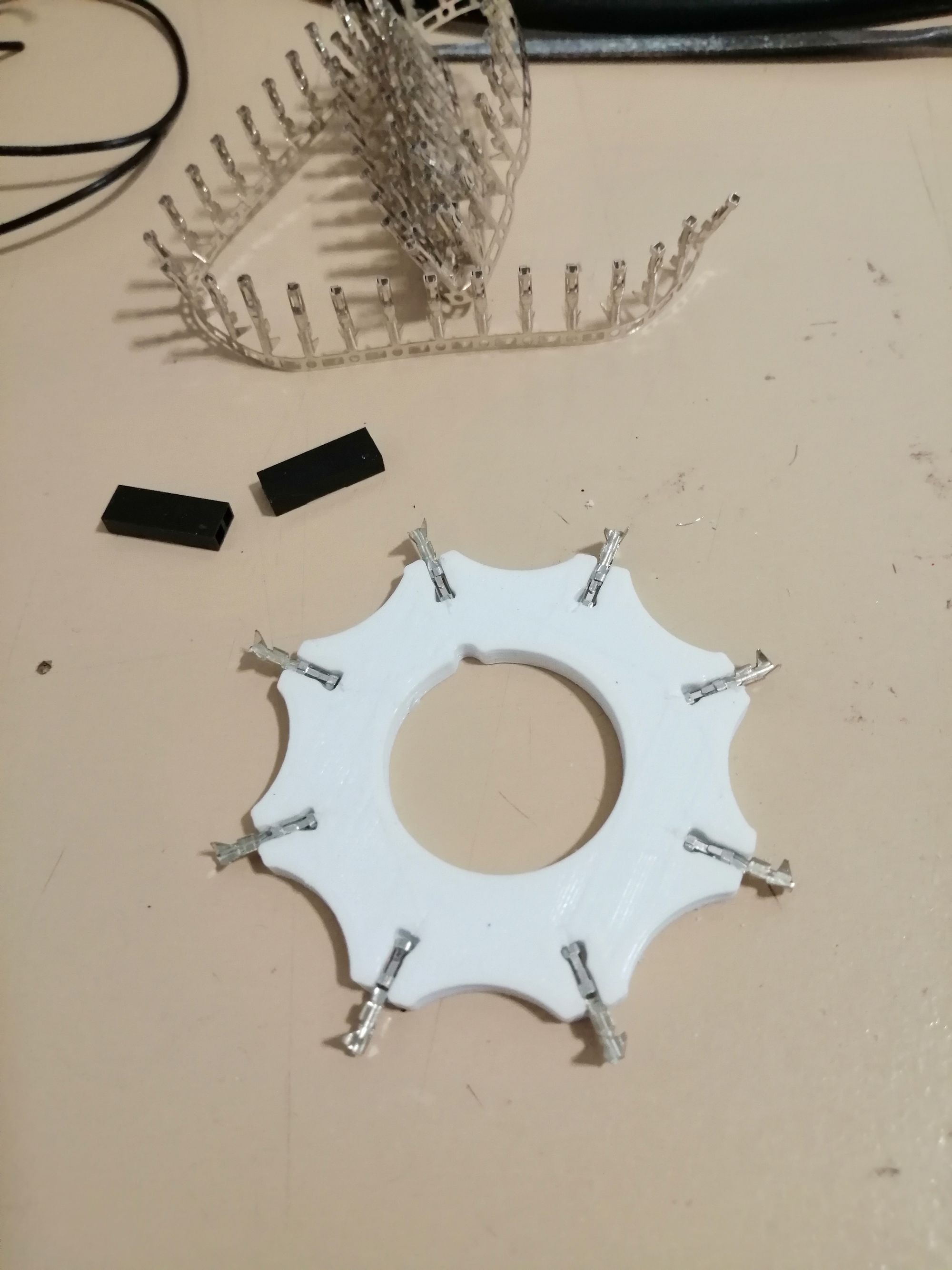

When it comes to dupont connectors, the problems really amounts to nothing other than orienting the connector in the crimping tool. Fat fingers always seem to get in the way. Here comes the 3d printer to the rescue!

A little jig that can be loaded easily with 8 conectors at one time, all with the correct orrientation and position ready to be inserted into the crimping tool

The crimping tool presses up to the jig and the connector is loaded into the tool at the correct depth. Then it is a simple matter to insert the wire and squeeze to crimp. A perfect crimp job every time without the need to struggle and fumble. A far more satisfying result.