Strange Vibe Sunday

It's not as though it's been a Ruslan Gatash "Strange Sunday" as I'm not a fan of what I can only assume is "jazz", but it still has been a Strange Vibe Sunday. One of those days when there are so many tasks to do that even achieving one of them leave you feeling empty inside.

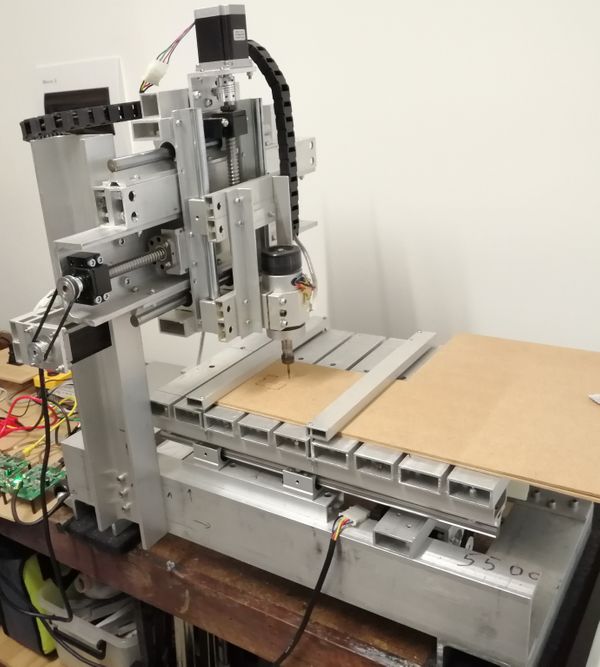

As it seems to be such a day today. In the arvo I decided to knock up a quick small PCB to distribute 5 and 12V power to a number of terminals ie nothing more than a power bus board. Fired up the CNC router to do the PCB milling and betterfingers me dropped the 0.4mm milling bit a whole 30mm but that was enough to snap off the tip. Well it seems to be like that but I need to check later as my eyesight is just not that good.

While it was busy milling away with an expensive new bit, I decided I really needed to do something about the way the circuitry is all spread over the work bench.

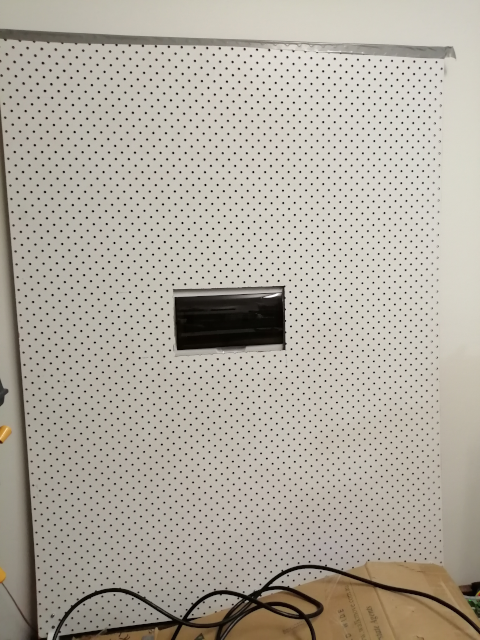

It is a painful and depressing short circuit just waiting to happen. Now, I could go an build some sort of.. hang on, what is the word???... "en...clo...sure" for it but that is definitely some time off. For now, I should just attach the few loose compnents and put the board up against the wall and drape something in front of it to stop stray metal shard ingress. To do that, I have to move the peg board that is currently occupying that space...

No matter how long I think about a it, I just cant get away from the fact there is a fuse box right in the middle of the board. Oh well.

Unloading all the tools off the peg board was a risky time - just one dropped tool/hook would instantly release the magic smoke from the CNC countroller as it was busy milling the PCB. But in the end, no tradgety and the board is in place.

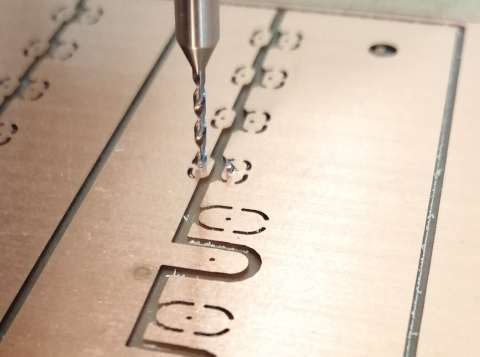

By then it was time to change the routing bit for a drill bit. All went well, the bit change homing procedure worked a treat. Hit the button for it to continue drilling and the head moved off to its 1st hole position. All good. Then is started lowering... waiting for the spindle to power up... no need to panic yet, it may just be getting to it's drill homing height... that position reach, still no spinning... come on, you can do it... almost on the board... come on... NOPE... crack.. crack crunch... head moves up for the next drill hole... Hit the abort button and that's me done for the day.

You can make out the fragment of the drill bit left in the board to the right of the shaft where it completely failed to press out a 1mm diameter cylinder of PCB.

Thinking back, this is the 1st time I've tried to mill a PCB since I made the toolchange code compatible with Fusion 360. Obviously I do not have a regression test suite... In no mood to debug gcode so </blog>

...Time passes...

Later that evening. Looks like the PCB tool change algorithm does not start up the spindle before it does the drill operation. Bugger.

G01[MOVE] Z-0.2000 F[SET_SPEED]508.0

G00[RAPID_POSITIONING] Z1.0000

M05[SPINDLE_OFF]

G04[DWELL] P3.000

(File:power-expansion.bot.drill.gcode)

(TOOLCHANGE: 1.0mm drill bit[0.0])

G00[RAPID_POSITIONING] F400.000 X38.903 Y68.114

G01[MOVE] F200.000 Z1.000

G01[MOVE] F75.000 Z-2.000

G01[MOVE] F200.000 Z1.000

Should not be too hard to fix